Depanning Systems

Designed for a wide variety of products, our automatic depanning systems increase your efficiency and eliminate the need for manual labor

Automatic Depanning

Built around your unique product and pan requirements, our custom depanning systems deliver reliable, hands-free performance at every stage.

Engineered for optimal performance, each system is customized to meet your specific pan and product requirements—maximizing throughput without compromising quality.

As a recognized leader in depanning technology, we understand its critical role in your production process. Whether installed as part of a new plant or integrated into an existing line, our flexible systems deliver reliable product handling, reduced waste, and consistently high-quality results.

Standard Inclusions

- Reliable Tooling & Attachment Design (Pattern & Method)

- Compliance With Latest Safety & Sanitation Standards

- Durable Construction & Hardware (High-Grade Stainless Steel)

- Easy Changeovers (Quick-Swap Tooling & Head Components)

- Simplified Operator Controls

- Wide Range of Depanning Components (customizable to suit a variety of product shape, size, or texture)

Varied Designs

Each design below can be customized with multiple tooling & attachment options to meet your specific needs:

- Inline Unit

- Modular Unit (Head, Conveyor, Blower)

- Pick & Place (single, dual, or quad-head)

- Scrabble

- Slap or Flip

- Rotary or Overturn

Tailored Options

Models are available with project-specific option attachments to boost productivity and operations. See more below:

- Delidders

- Oil & Debris Collection

- Seed Containment Hood

- Air Jet Assembly

- Vacuum Cup Cleaner & Start Up Kit

- Pan Detection Sensors

Blower Module

The air from the vacuum chamber undergoes filtration through a Stainless Steel bag filter and oil collection module before entering the blower, minimizing oil, seed, and crumb buildup. This eliminates the need for costly cleaning, optimal particle filtration, and downtime, ensuring premium blower efficiency.

Cyclone Separator

Strategically positioned between the vacuum head and the blower module, the cyclone separator efficiently removes airborne particles and oil from the air stream. This yields cleaner air, which reduces the environmental impact, and enhances the overall system performance.

Vacuum Belting

- Ideal for lightweight, delicate products

- Continuous, gentle product removal

- Maintains product shape and surface integrity

Needle Head

- Best for uniform products like muffins or cupcakes

- Food-grade needles lift products cleanly from pans

High-speed, accurate performance with minimal waste

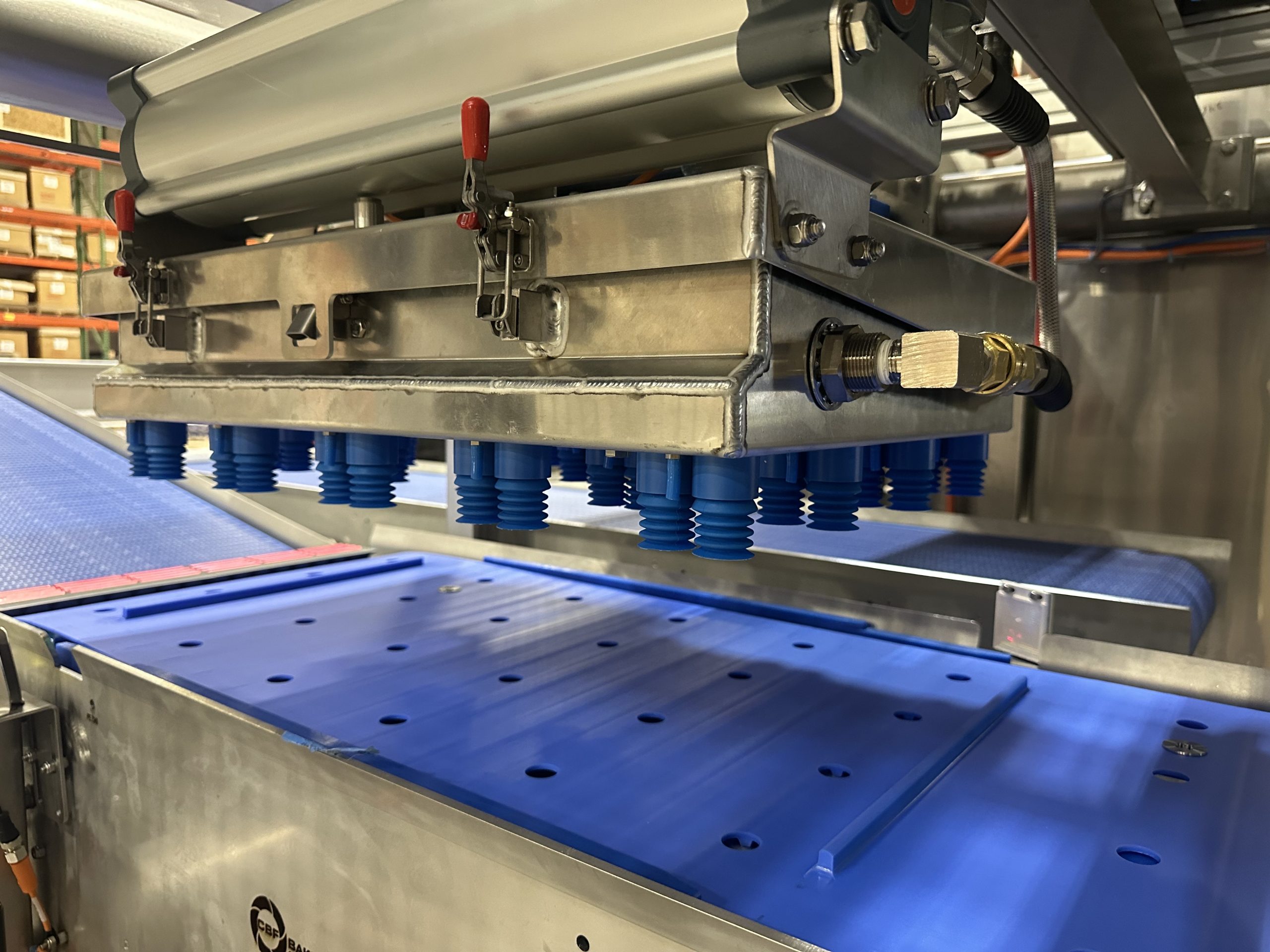

Vacuum Gripper Head

- Flexible handling for irregular or fragile items

- Uses individual vacuum cups for precision pickup

- Great for a wide variety of product shapes and sizes

Pneumatic Clamp Head

- Designed for heavier or firmly seated products

- Adjustable clamps provide a secure mechanical grip

- Durable and reliable under high-throughput conditions

Versatile Equipment

- Supplied as standalone units or integrated into larger systems

- Decreased changeover & downtime

- Decreased reliance on manual labor

- Lower operational risks

- Minimize waste production

- Operation & maintenance-friendly features

- Reduced operating costs

- State-of-the-art control systems

- USDA-compliant designs for sanitation in washdown environments

- Dynamic layout capabilities

Automation for Safety & Cost Reduction

Our machines are designed to deliver a high degree of precision and control quality, in addition to, enhancing safety protocols and reducing operational costs.

Collaborative Approach

From beginning to end, we work closely with your team to ensure the development of a one-of-a-kind solution aligned with your specific needs.

Comprehensive Installations & Training

We go beyond just delivering machines. Our commitment extends to installations and training empowering seamless integration.

Personalized Customer Service

As a family-owned business, we prioritize personalized customer service, ensuring that your unique needs are understood and met with a dedicated approach.

Shortest Lead Times

We strive for the quickest turnaround times in the industry. From conception to completion, we can help you minimize costly downtime of your operations.

Elevate your bakery operations with our expertise!

CBF Bakery Systems stands ready to make your production process more efficient and cost-effective.

To learn more contact us via phone call, email, or link provided.