PRODUCT CONVEYING, HANDLING, & COOLING SYSTEMS

Experience unparalleled efficiency and reliability with our customized conveying solutions tailored to accommodate a diverse range of products and bakery layouts

Product Conveying Solutions

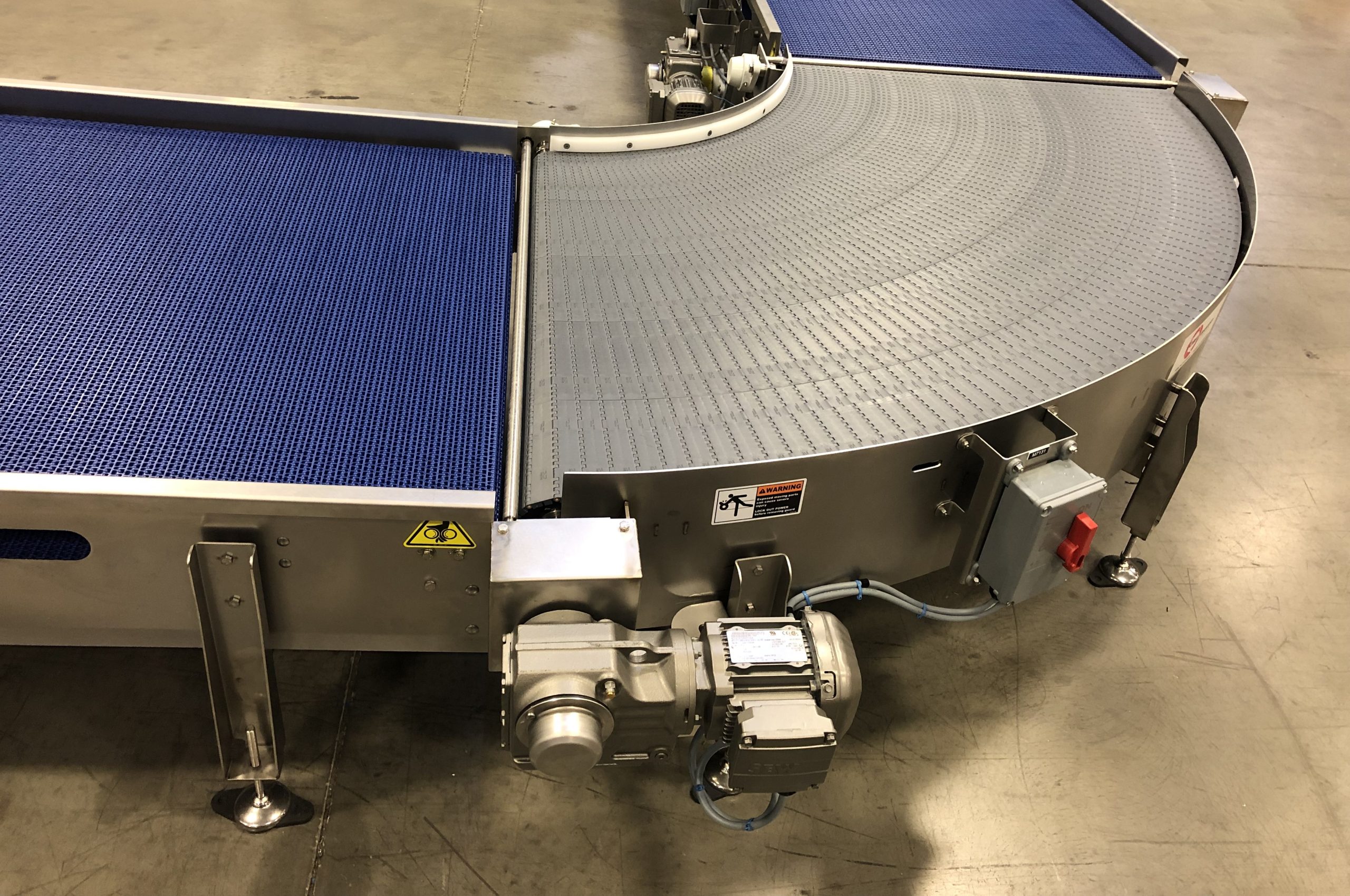

At CBF Bakery Systems, we specialize in crafting customized conveying solutions tailored to accommodate a diverse range of products and bakery layouts. Our conveying systems are meticulously designed with a focus on ease of use, low maintenance, and optimal sanitation, aiming to eliminate product damage during accumulation and transfers while enhancing downstream processes.

Integrate CBF Bakery Systems' conveying solutions into your bakery operations to experience a seamless blend of efficiency, safety, and compliance with the most rigorous food industry standards.

Trust CBF Bakery Systems for seamless and reliable conveying, handling, and cooling of all your products, every day.

General Construction Features

- All Stainless Steel construction for durability and hygiene

- C-Channel support legs with adjustable feet and standoffs for stability

- Chrome or Stainless Steel shafting for robust performance

- Low maintenance design

- Shaft mount motors with Stainless Steel taper locks for efficient operation

- Stainless Steel Bearings with standoffs and metal detectable safety caps

- Stainless Steel NEMA 4X construction

- State-of-the-art control systems matching industry standards

- PLC controlled for precision

- Prewired to motor disconnects for easy installation

- Welded or Stainless Steel bolted construction ensuring structural integrity and longevity

- UL Approved

Sanitation & Safety Features

- Design minimizing flat surfaces to facilitate easy cleaning

- Full washdown USDA construction available

- Sanitary adjustable feet with no exposed threads

- Sanitary construction ensures compliance with the highest food industry standards

- No metal-to-metal contact throughout the design, promoting longevity and hygiene

- One-piece UHMW belt supports for stability and easy cleaning

- Use of all blue UHMW for visual contamination detection

- Guarding available with hinges and integrated safety sensors

Conveyor Options

Our product conveyors can be equipped with various conveying options:

- Air Jet / Knife Assembly

- Catch Pans / Trays

- Belt Brushes

- Catch Tarps

- Belt Lifts

- Safety Netting

- Belt Scrapers

- Sanitary Covers

- Belt Washer / Wash Skid

- Spray Bars

Belt Options

Our product conveyors can be equipped with various belting options:

- Acetyl

- Nylon

- Polypropylene

- Polyurethane

- Stainless Steel

- Ashworth

- Cambridge

- Habasit

- Intralox

- Uni-Ammeraal

Versatile Equipment

- Supplied as standalone units or integrated into larger systems

- Decreased changeover & downtime

- Decreased reliance on manual labor

- Lower operational risks

- Minimize waste production

- Operation & maintenance-friendly features

- Reduced operating costs

- State-of-the-art control systems

- USDA-compliant designs for sanitation in washdown environments

- Dynamic layout capabilities

Conveyor Hygienic Levels

| Type 1 – Standard | Type 2 – Full Washdown (Sanitary) | |

| Environmental Conditions |

|

|

| Mechanical Construction |

|

|

Automation for Safety & Cost Reduction

Our machines are designed to deliver a high degree of precision and control quality, in addition to, enhancing safety protocols and reducing operational costs.

Collaborative Approach

From beginning to end, we work closely with your team to ensure the development of a one-of-a-kind solution aligned with your specific needs.

Comprehensive Installations & Training

We go beyond just delivering machines. Our commitment extends to installations and training empowering seamless integration.

Personalized Customer Service

As a family-owned business, we prioritize personalized customer service, ensuring that your unique needs are understood and met with a dedicated approach.

Shortest Lead Times

We strive for the quickest turnaround times in the industry. From conception to completion, we can help you minimize costly downtime of your operations.

Elevate your bakery operations with our expertise!

CBF Bakery Systems stands ready to make your production process more efficient and cost-effective.

To learn more contact us via phone call, email, or link provided.